Precision Engineering

Total control of the production cycle.

01 Design

Our engineering unit uses advanced CAD/CAM software to transform architectural concepts into functional three-dimensional models. More than just designing, we simulate the thermal and mechanical integration of each luminaire before it enters production, ensuring technical feasibility from the first sketch.

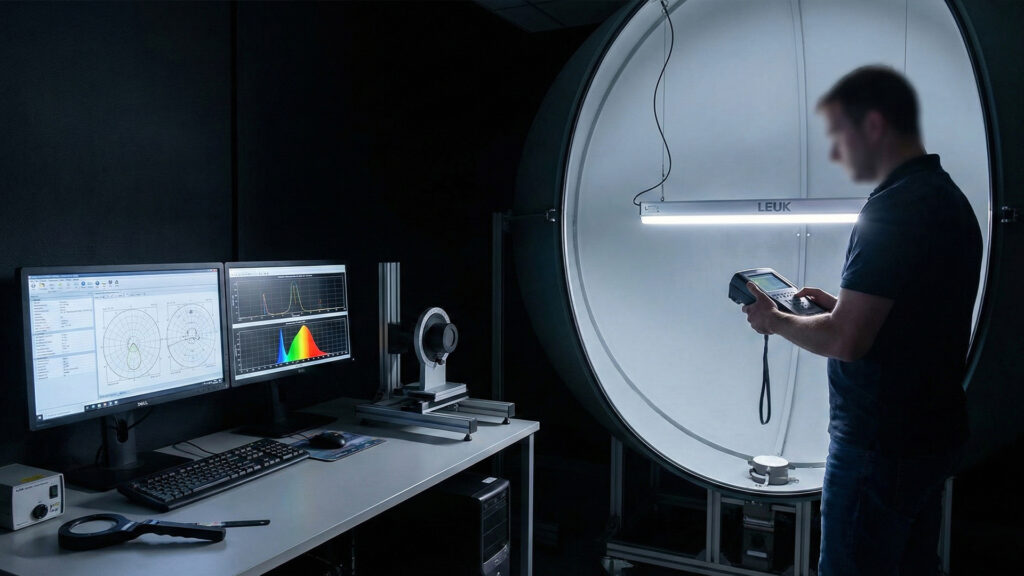

02 Validation and Lighting Study

Light is science. In our in-house laboratory, equipped with integrating spheres and high-precision goniophotometers, we validate luminous flux, color temperature, and color rendering index (CRI). We provide validated LDT/IES files to ensure that the project simulation corresponds exactly to the reality on site.

03 Quotation and Customer Support

We have developed an algorithmic quoting system that crosses stock data, production times, and raw material costs in real time. This allows us to deliver accurate and competitive quotes for complex projects in record time, supported by a multilingual technical assistance team.

04 Profile Machine

Precision begins at the structure. Our aluminum profile machining center operates fully automatically, capable of processing bars up to 6.5 meters with tolerances below 0.2mm. This precision ensures a perfect fit in continuous line systems and complex structures.

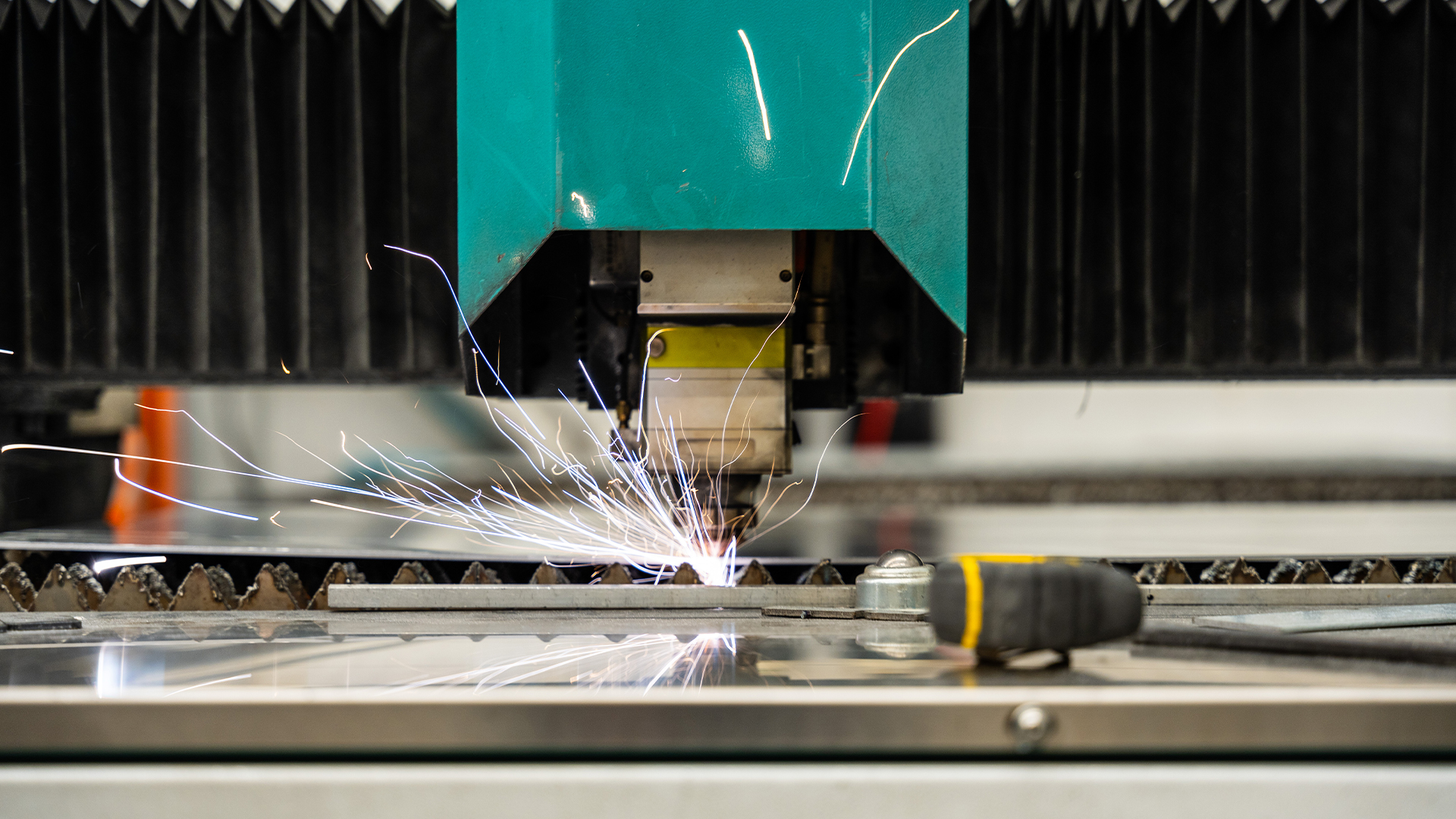

05 Laser Cutting

Shape flexibility is ensured by our fiber laser cutting cell. With the capacity to cut sheet metal up to 20mm thick, we eliminate the need for external molds, allowing for the rapid production of custom parts, special brackets, and robust structural components.

06 Sheet Metal Bending

The transformation of flat sheet metal into three-dimensional components is performed by state-of-the-art CNC bending machines. Digital control of the bending angle ensures exact repeatability in large series, guaranteeing that each luminaire maintains the perfect geometry designed by our engineers.

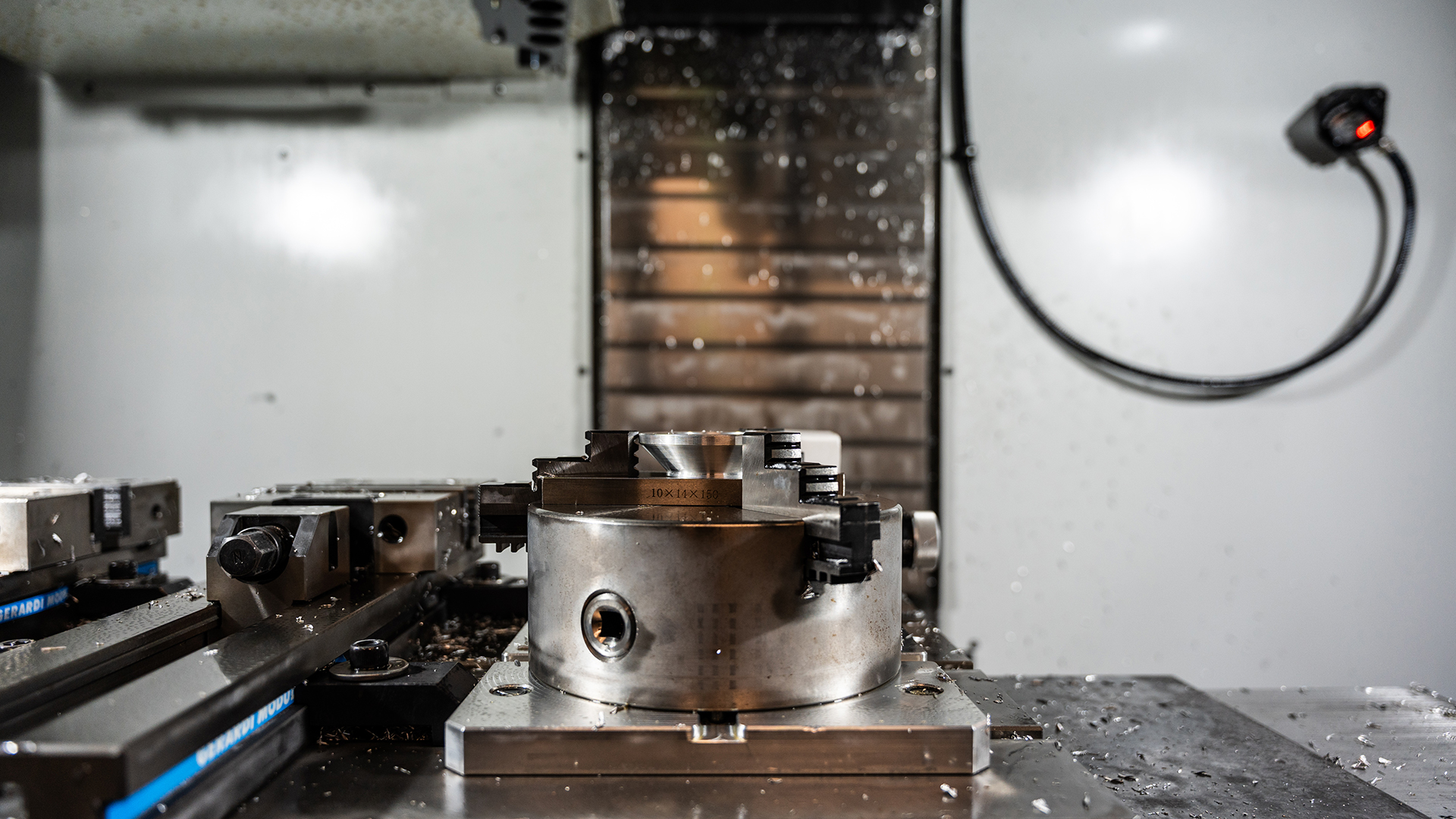

07 Milling

For the most refined details and micro-precision components (such as those in the TUBE range), we use 5-axis CNC machining centers. This in-house milling capability allows us to create custom heat sinks and complex mechanical parts that the standard market does not offer.

08 IP68 LED Encapsulation

Our proprietary LED Potting (Encapsulation) technology creates an indestructible airtight barrier. By involving electronics in high-transparency polymer resins, we provide IP68 protection and IK10 impact resistance, making our luminaires immune to water, dust, UV rays, and chemical corrosion.

09 Powder Coating

The surface finish is ensured by our automatic powder coating line, certified by the QUALICOAT standard. The process includes chemical pre-treatment of the metal for maximum adhesion, resulting in a uniform, scratch-resistant surface with superior durability in harsh environments.

10 Electronic Assembly and QC

In the final phase, specialized technicians integrate the PCBs (Printed Circuit Boards), drivers, and optics. Each assembled unit undergoes rigorous Quality Control (QC), including electrical insulation tests and burn-in testing to ensure flawless reliability.

11 Packaging

We do not use standard boxes. Our Packaging On-Demand machine produces packaging cut to the exact size of each luminaire, regardless of its length or shape. This minimizes material waste and ensures maximum structural protection during transport.

12 Shipping

Our logistics center manages the shipping flow to several countries. With an integrated tracking system and strategic transport partnerships, we ensure that the material arrives at the site at the right time, properly conditioned and ready for installation.

Certified Quality (ISO 9001:2015)

Excellence is not an isolated act, it is a validated habit. Our company is ISO 9001:2015 certified, reflecting our culture of continuous improvement and full traceability — covering everything from product development to after-sales support.

Because we fully control the production process, we can monitor every component to ensure compliance with the most demanding European safety and performance standards. This industrial autonomy allows us to develop standard products or create new custom-made parts in record time.

To support this operation, we have commercial and quality management teams present in several countries. With specialized knowledge, we support our clients in all critical phases: from design and installation to after-sales service, ensuring a rapid response to any challenge.